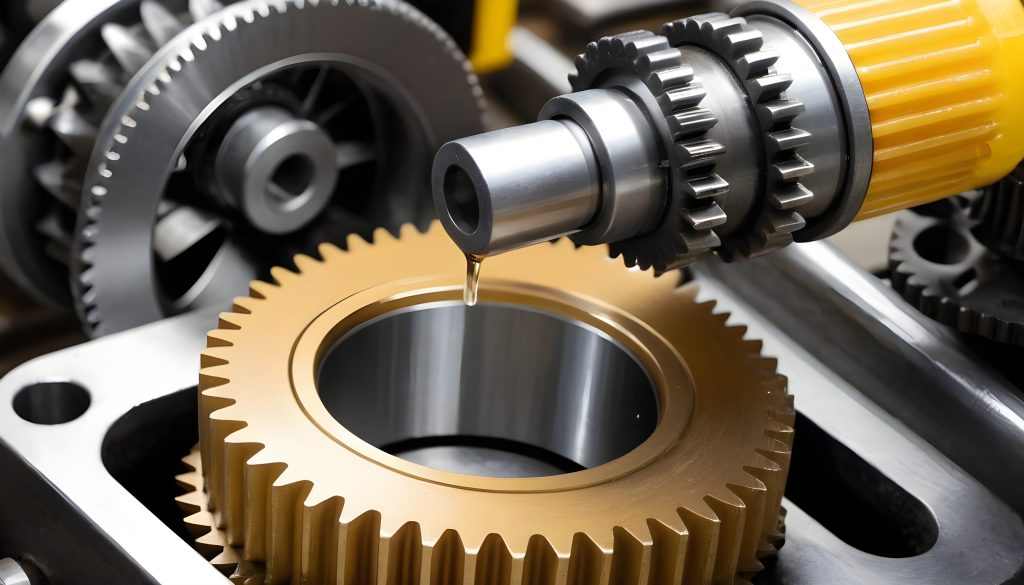

Operating industrial machinery in extreme environments presents unique lubrication challenges, including high temperatures, heavy loads, and corrosive conditions. Effective lubrication strategies are crucial for ensuring optimal performance and extending equipment lifespan in such harsh conditions.

Selecting the right lubricant is paramount in addressing these challenges. Traditional lubricants may not withstand extreme temperatures or corrosive agents, necessitating the use of specialized high-temperature or corrosion-resistant lubricants. These lubricants provide essential protection and lubrication for machine components subjected to extreme conditions.

In high-temperature environments, lubricants with high thermal stability are essential to resist thermal degradation and maintain lubricating properties. Synthetic lubricants, known for their superior heat resistance, are commonly utilized in such applications. Additionally, incorporating solid lubricants like molybdenum disulfide or graphite can offer additional protection under extreme heat conditions.

Heavy loads impose another significant challenge for lubrication in industrial machines. Conventional lubricants may fail to provide adequate film strength to prevent metal-to-metal contact and wear under high loads. Employing high-viscosity lubricants or extreme pressure additives can enhance film strength and protect components from premature failure.

Corrosive environments pose a considerable threat to machine components, as corrosive agents can degrade lubricants and damage metal surfaces. Selecting lubricants with corrosion inhibitors or anti-rust additives is crucial to safeguard components and prolong their lifespan. Regular inspection and maintenance of lubricated components are also essential to detect and address any signs of corrosion early.

In conclusion, lubrication is indispensable for mitigating the challenges posed by extreme environments in industrial machinery. By selecting the right lubricants and implementing appropriate lubrication strategies, companies can ensure optimal performance, minimize downtime, and extend equipment lifespan even in the most demanding operating conditions. Investing in high-quality lubricants and proactive maintenance practices is paramount for success in extreme environments.

To get the best on lubricants that we recommend for your machineries, do contact us for more information